These images show some examples of how the Dye-Lishus® cotton can be used. Much of it is about differential dyeing, which means that different fibers accept dye differently in the cloth. The "different fibers" can be cellulosic/polyester, cellulosic/protein, etc. Or, fibers of the same class can be dyed differently with different mordants or other treatments. So here are cottons, treated and untreated.

Jump to Fabric

|

Fiber: Dyeing cotton fiber is normally pretty complex, and if you want to dye it with natural dyes, the process is even more involved. Now you can take this Dye-Lishus® cotton sliver, wet it out, and just dye it with anything. Really. It accepts acid, direct, fiber reactive, and natural dyes. Union dyes are a combination of acid and direct, designed to dye all natural fibers. The direct dyes are taken up in cellulosics and the acid dyes are taken up in protein fibers. This cotton accepts both. In the photo are natural dyes, food coloring, and fiber reactive dyes. You could use direct or union dyes too if you are just dyeing the sliver by itself. If you are dyeing fabric with other colors, the direct dye will overdye the colors. An originally white yarn will be a lighter shade than the Dye-Lishus® cotton, because the Dye-Lishus® cotton will accept both the acid and direct dye in the dyebath.

|

|

|

Yarn: 2 or 4 shaft Log Cabin, dyed after weaving Weave this on a rigid heddle loom or a floor loom with 4 shafts. It's just plain weave. Color and weave on one warp; many pieces can be woven on one warp and dyed different colors after weaving in solids, or used in shibori, or space dyed. These other colors will not change in the dyepot. Here I alternated regular white cotton with treated Dye-Lishus® cotton in both warp and weft. An additional black thread offsets the sequence and gives a border for squares or rectangles. The white cotton stays white throughout when dyed with natural or fiber reactive dyes. Using a union dye that contains both acid and direct dyes (Rit or Dylon) will dye both yarns. The regular cotton does not need to be white, it can be any color of your choosing. |

|

|

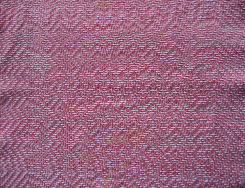

Yarn: 4 shaft 2/2 twill stripes or checks, dyed after weaving. Of course you could weave plain weave on 2 shafts. The warp contains a stash yarn that bleeds red. Here's how to use it! The top patch is unfinished, right untreated white crossing Dye-Lishus® cotton, and left is Dye-Lishus® cotton crossing Dye-Lishus® cotton.Dyed by dunking in boiling water after removing from the loom. No other dye was used, just that which bled from the red yarn. It could be overdyed if the color is too pale. |

|

|

Yarn: 8 shaft Reversing Twill Color & Weave, dyed after weaving Color & weave, 2 shuttles. 3/1 vs 1/3 twill blocks. I just used the same color sequence in all of the blocks, warp & weft. The undyed is on the far right; I used a space dyed yarn from my stash. Here is a way to use that yarn you love to look at but won't use because you know it bleeds. If you make this cloth, then toss it in very hot, even boiling, water, the color in the stash yarn will bleed and be taken up by the Dye-Lishus® cotton. In this case, the red bleeds and gives a pink background. I dyed the gold and the blue pieces in cold water, so the red did not bleed. |

|

|

Yarn: 16 shaft Reversing Twill Color & Weave, dyed after weaving (download wif file) Color & weave, 2 shuttles. This is a very simple way to design color and weave if you have 6 or more shafts. I took a birdseye pattern from Davidson and did block substitution, replacing with 1/3 vs 3/1 twill with the same color sequence in each block. I used a space-dyed yarn as the color and dyed the samples with fiber reactive dyes. |

|

|

Yarn: 8 shaft Bronson Spot, dyed after weaving (download wif file) Color & weave, 2 shuttles. You can do it on 6, but I shifted half of the ground threads to shafts 3 & 4. It also allows me to invert the pattern so I can get weft floats as well as warp floats on the same side. |

|

|

Yarn: 8 shaft Diversified Plain Weave, dyed after weaving (download wif file) Color & weave, 2 shuttles. I insist it's just 3-thread huck. But whatever you call it, the ground threads are thin and the pattern threads are thick. Here I used 10/2 and 5/2, in organic and Dye-Lishus® cottons. Thick & thin were opposite colors in warp & weft. The fabric weight is perfect for towels. You could use the 5/3 for an even cushier towel. You can see how to design for this weave structure here. |

|

|

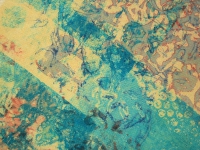

Fabric: Dye your own shot cotton download document If you currently dye with fiber reactive or natural dyes, you are familiar with using the mordants or auxiliary chemicals to get your color to stick. The fabrics are made with an untreated cotton warp and some or all of the weft is treated. So if you want to dye both, in different colors, you should first dye the Dye-Lishus® portion, then treat the way you usually do to over dye the Dye-Lishus® cotton and dye the white part. So the Dye-Lishus® cotton gets dyed and then overdyed. Here the fabric was first dyed blue, then two pieces were treated, with one being dyed red and the other yellow. |

|

|

Fabric: Snow Dyeing Dyes: Kool Aid! Before and after; snow piled on top of scrumbled, wet fabric. Powders sprinkled over the snow. Snow left to melt overnight. Rinsed, washed, dried, and cut up to put in a patchwork with a commercial fabric. |

|

|

Fabric: Deconstructed Screen Print Dyes: Procion MX Deconstructed screen print by Betsy Morrill. Fabric Dye-Lishus® cotton pixellated, dyed yellow, then printed. Heat setting not necessary. |

|

|

Fabric: Tie dye Dyes: Procion MX Tie dye the stripes to make it look like ikat. Stitch to embellish. |

|